8 Year Exporter Rotary Pleating Machine - 300mm HEPA Filter paper pleating production line – Anya

8 Year Exporter Rotary Pleating Machine - 300mm HEPA Filter paper pleating production line – Anya Detail:

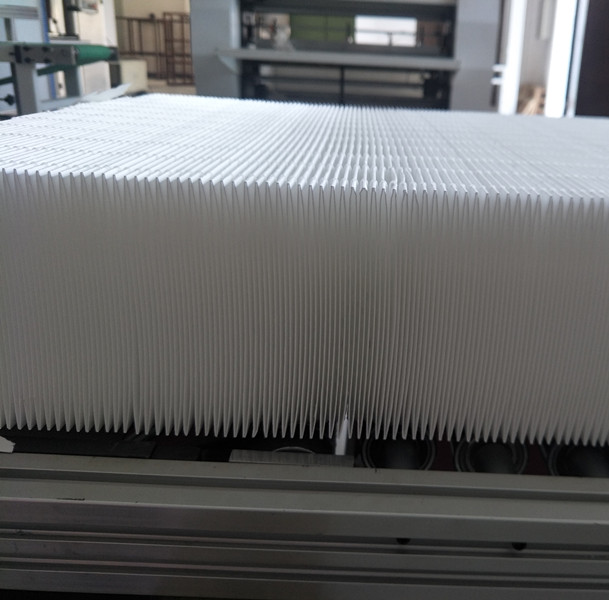

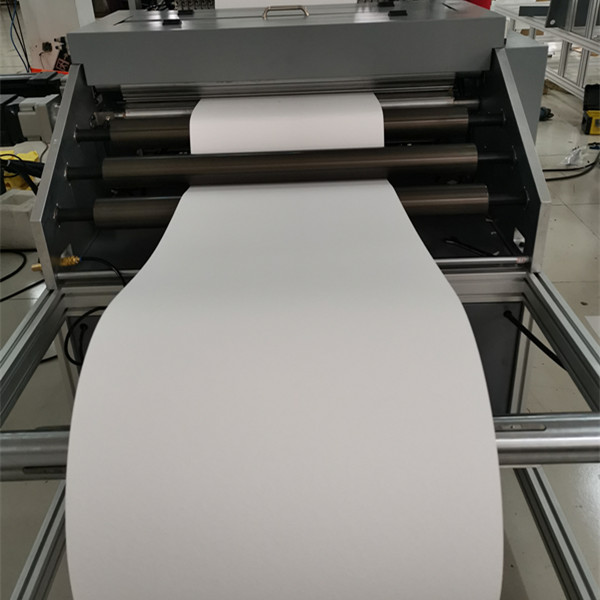

The imported slitting unit is used on the production line, which make sure the cutting end face flat and no rough edges. The pleat height(20-300mm) is adjustable by the different speed between marking roller and carry-over pin roller. The users don’t need to change the roller, which improve working efficiency. There is one independent valve for each hot melt nozzel, so we can control the continuous and intermittent gluing on filter paper to be suitable for different specifications and models of filter products(the max width is 700mm). It is easily to operate the machine because of PLC program control and touch screen operation. There is cooling system which can make sure the gluing line on final pleating paper solidified once pass through on conveyor belt. So the users can cut the pleating paper easily. The long conveyor belt can be suitable for different

Product detail pictures:

Related Product Guide:

Samsung announces the Galaxy Fold, a phone that opens into a tablet | F6 Pocket Filter Media

Forget Drone Racing – Quadcopter (With Pilot Inside) Racing Series Set To Be ‘Formula One Of The Skies’ | Filter Paper Pleating Machine

No matter new customer or old customer, We believe in long term and trusted relationship for 8 Year Exporter Rotary Pleating Machine - 300mm HEPA Filter paper pleating production line – Anya , The product will supply to all over the world, such as: Ghana , France , Angola , We have top engineers in these industries and an efficient team in the research. What is more, now we have our own archives mouths and markets in China at low cost. Therefore, we can meet different inquiries from different clients. Remember to find our website to check more information from our merchandise.

Speaking of this cooperation with the Chinese manufacturer, I just want to say"well dodne", we are very satisfied.