Factory Outlets Folding Adhesive - Full Auto Folding Type Face Mask Production Line – Anya

Factory Outlets Folding Adhesive - Full Auto Folding Type Face Mask Production Line – Anya Detail:

Production process:

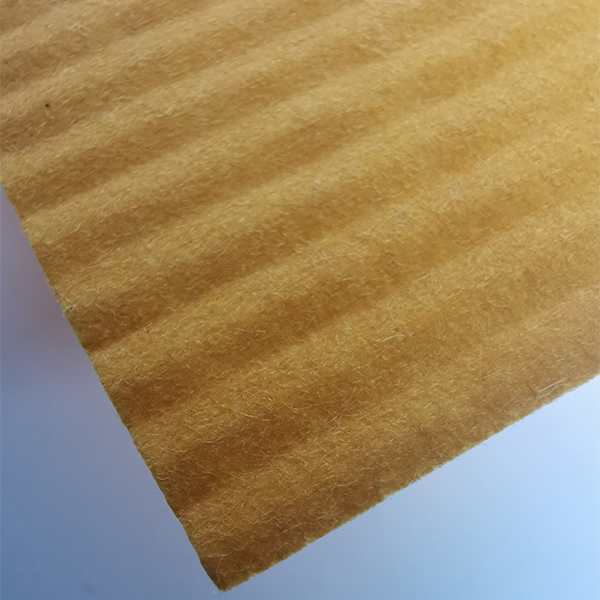

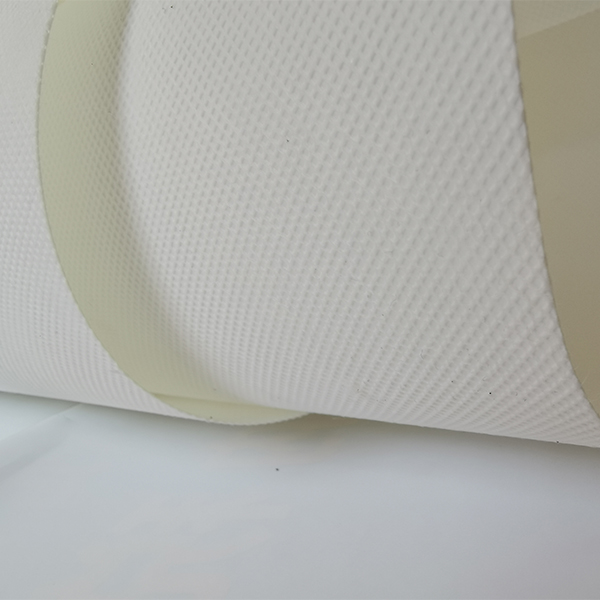

1. Multireel media feeding (can custom spare feeding roller)

2. Built-in nose bridge strip

3. Edge sealing and welding

4. Sticking sponge strip

5. Spraying code (leave blank in the position, customer can select)

6. Welding ear loop (both round and flat loop can be produced)

8. Folding the mask

9. Sealing and welding the edge after fold

10. Alignment fine-tuning

11. Ear loop blowing up

12. Rolling the cutter

Specification:

Machine size: 9650mm*2140mm*1500mm

Ear loop length: 130mm+20mm

Media Width:260mm

Product welding teeth and cutting position deviation +1mm

Tolerance of nose bridge strip length: +2.5mm (The nose bridge strip is 5mm*0.7mm, plastic with built-in iron wire)

Production capacity: 30-50pcs/min

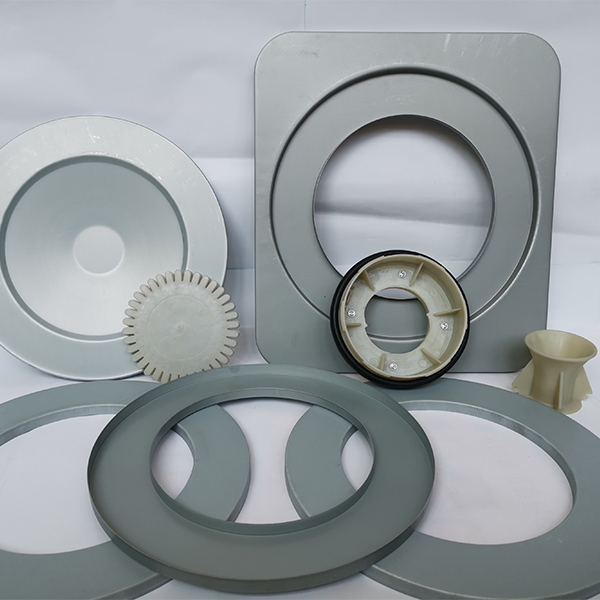

Product detail pictures:

Related Product Guide:

Independent Spirit Awards 2019: Chloe Grace Moretz puts her chest on display | F7 Glassfiber Air Filter Paper

Global Bioadhesives for Packaging Market Insights, Forecast to 2025 | Aluminum Frame

Our well-equipped facilities and excellent quality control throughout all stages of production enables us to guarantee total customer satisfaction for Factory Outlets Folding Adhesive - Full Auto Folding Type Face Mask Production Line – Anya , The product will supply to all over the world, such as: Romania , Mombasa , Luxemburg , With the superior and exceptional service, we've been well developed along with our customers. Expertise and know-how ensure that we are always enjoying the trust from our customers in our business activities. "Quality", "honesty" and "service" is our principle. Our loyalty and commitments remain respectfully at your service. Contact Us Today For further information, contact us now.

The product manager is a very hot and professional person, we have a pleasant conversation, and finally we reached a consensus agreement.

Write your message here and send it to us