Manufacturing Companies for Mini Pleating Machine - PU gule Two component Polyether polyols for air filters – Anya

Manufacturing Companies for Mini Pleating Machine - PU gule Two component Polyether polyols for air filters – Anya Detail:

Instructions:

1. Material-A should stirred evenly with plastic hand electric drill, material-B can shake, before used.

2. Open the electrocaloric plate temperature to 40-50 degrees, in winter material-A and material-B with a small container to preheat.

3. Wipe the mould with release agent

4. According to the local environment, such as the humidity in the air, workshop environment.

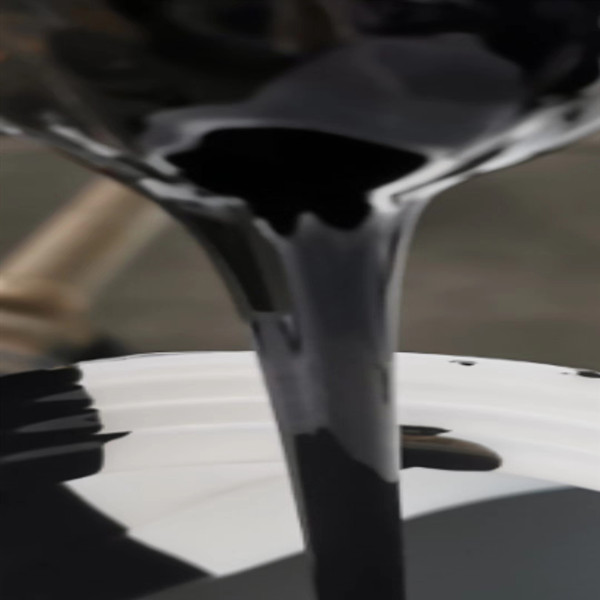

5. material-A and material-B are mixed at the mixture ratio of 100:40 ratio, then add 40% talcum powder(heavy calcium powder)(100:40:50±5), with 2800 rev / min motor to mix, mixing time determined by the amount of adhesive, per 100g of adhesive is approximately 7-10 seconds .

6. Pour the Mixed liquid into mould, then put the paper element and give a little pressure on it. 8-15 minutes later you can bring the mould down

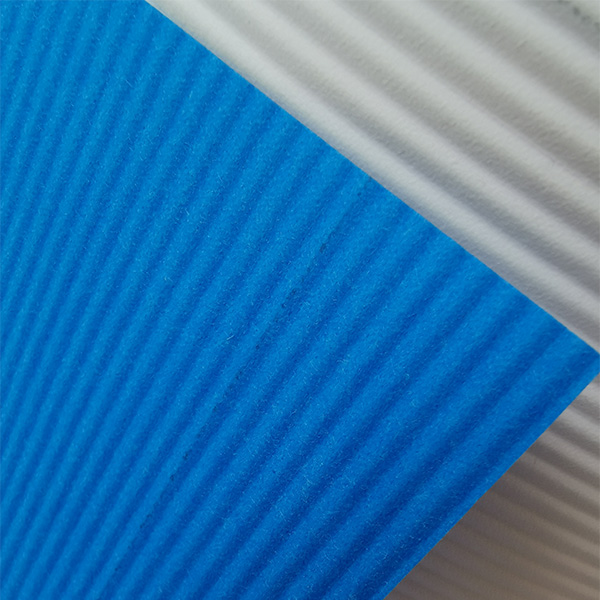

Product detail pictures:

Related Product Guide:

Lupita Nyong’o went on 10-day silent retreat following Black Panther success | F6 Pocket Filter Media

Johnny Depp’s new Russian go-go girlfriend Polina Glen shows off her moves aged 17 | F6 Pocket Filter Media

Our progress depends about the advanced products ,fantastic talents and continuously strengthened technology forces for Manufacturing Companies for Mini Pleating Machine - PU gule Two component Polyether polyols for air filters – Anya , The product will supply to all over the world, such as: Sudan , New Zealand , Naples , Our company, is always regarding quality as company' s foundation, seeking for development via high degree of credibility , abiding by iso9000 quality management standard strictly , creating top-ranking company by spirit of progress-marking honesty and optimism.

In general, we are satisfied with all aspects, cheap, high-quality, fast delivery and good procuct style, we will have follow-up cooperation!