New Delivery for F7 Pocket Filter Media - 300mm HEPA Filter paper pleating production line – Anya

New Delivery for F7 Pocket Filter Media - 300mm HEPA Filter paper pleating production line – Anya Detail:

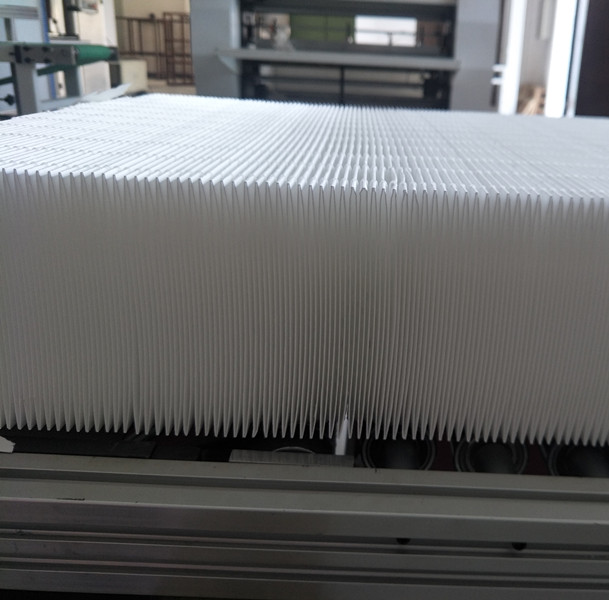

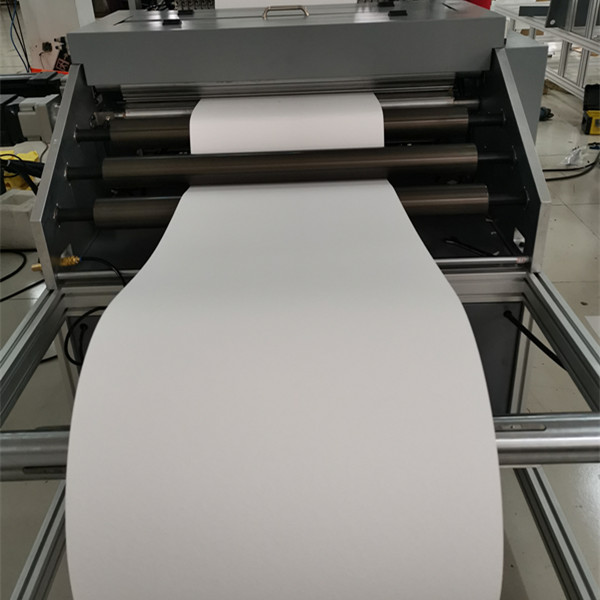

The imported slitting unit is used on the production line, which make sure the cutting end face flat and no rough edges. The pleat height(20-300mm) is adjustable by the different speed between marking roller and carry-over pin roller. The users don’t need to change the roller, which improve working efficiency. There is one independent valve for each hot melt nozzel, so we can control the continuous and intermittent gluing on filter paper to be suitable for different specifications and models of filter products(the max width is 700mm). It is easily to operate the machine because of PLC program control and touch screen operation. There is cooling system which can make sure the gluing line on final pleating paper solidified once pass through on conveyor belt. So the users can cut the pleating paper easily. The long conveyor belt can be suitable for different

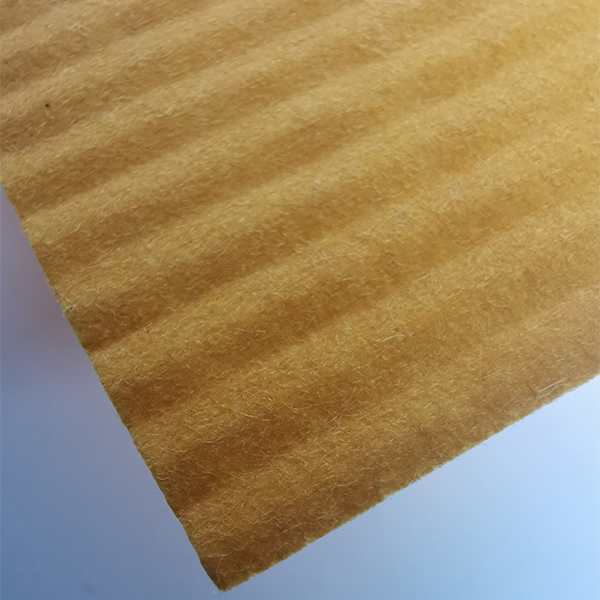

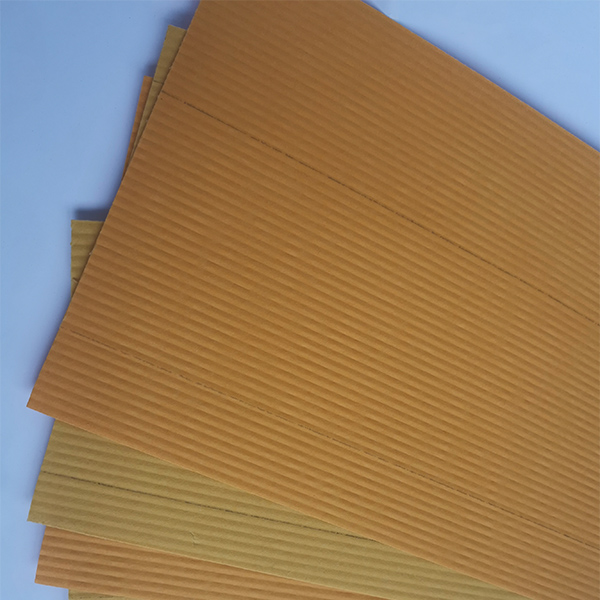

Product detail pictures:

Related Product Guide:

‘Honor their sacrifice’: Vietnam memorial, The Wall that Heals, coming to Greenfield | Folding Adhesive

Shanina Shaik and husband DJ Ruckus attend UNICEF gala in Sardinia | Folding Adhesive

Our primary target will be to provide our clients a serious and responsible small business relationship, supplying personalized attention to all of them for New Delivery for F7 Pocket Filter Media - 300mm HEPA Filter paper pleating production line – Anya , The product will supply to all over the world, such as: Brasilia , Slovenia , kazakhstan , With the goal of "zero defect". To care for the environment, and social returns, care employee social responsibility as own duty. We welcome friends from all over the world to visit and guide us so that we can achieve the win-win goal together.

Good quality, reasonable prices, rich variety and perfect after-sales service, it's nice!