Wholesale Dealers of Filter Cap - 300mm HEPA Filter paper pleating production line – Anya

Wholesale Dealers of Filter Cap - 300mm HEPA Filter paper pleating production line – Anya Detail:

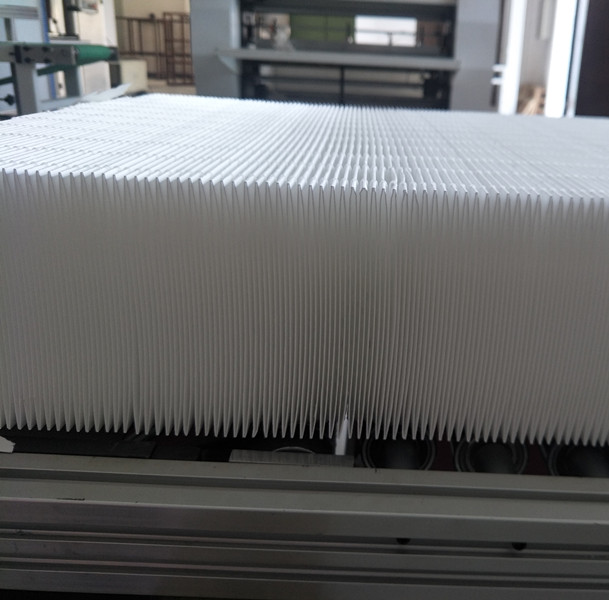

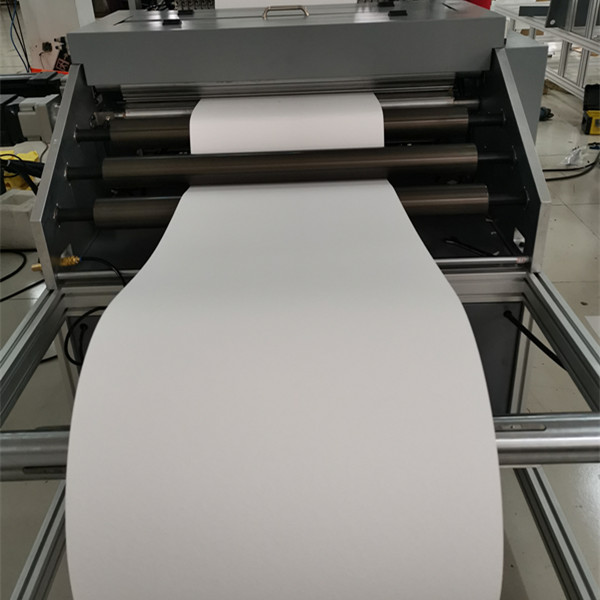

The imported slitting unit is used on the production line, which make sure the cutting end face flat and no rough edges. The pleat height(20-300mm) is adjustable by the different speed between marking roller and carry-over pin roller. The users don’t need to change the roller, which improve working efficiency. There is one independent valve for each hot melt nozzel, so we can control the continuous and intermittent gluing on filter paper to be suitable for different specifications and models of filter products(the max width is 700mm). It is easily to operate the machine because of PLC program control and touch screen operation. There is cooling system which can make sure the gluing line on final pleating paper solidified once pass through on conveyor belt. So the users can cut the pleating paper easily. The long conveyor belt can be suitable for different

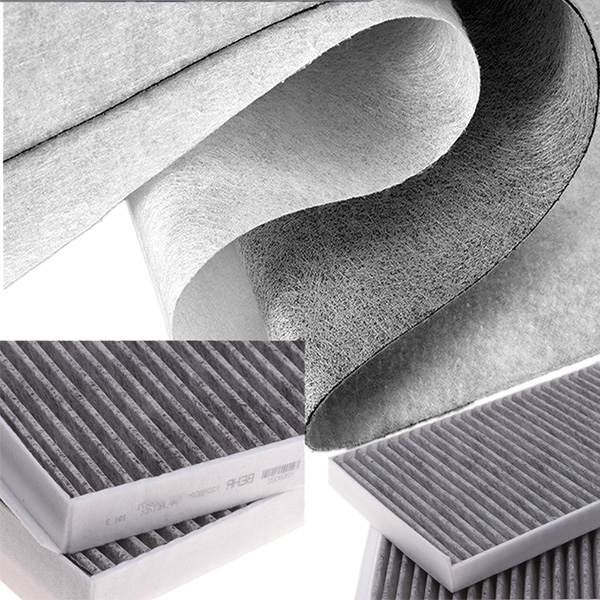

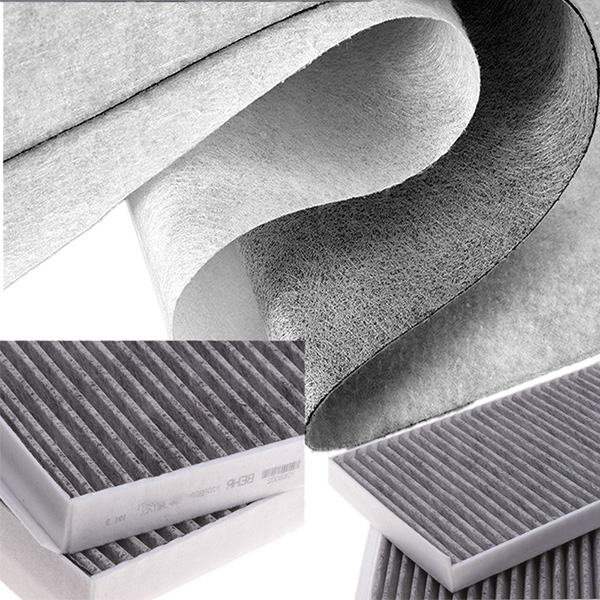

Product detail pictures:

Related Product Guide:

Eva Longoria looks chic during a photoshoot with her son Santiago at Cannes Film Festival | F7 Glassfiber Air Filter Paper

The Xmera Bionic Bike Lets You Work Out During Your Commute | Aluminum Frame

We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate in our success for Wholesale Dealers of Filter Cap - 300mm HEPA Filter paper pleating production line – Anya , The product will supply to all over the world, such as: Greece , Vietnam , Mauritius , Our advantages are our innovation, flexibility and reliability which have been built during last 20 years. We focus on providing service for our clients as a key element in strengthening our long-term relationships. The continual availability of high grade products in combination with our excellent pre- and after-sales service ensures strong competitiveness in an increasingly globalized market.

Products and services are very good, our leader is very satisfied with this procurement, it is better than we expected,